A6426

Antifoam 204

mixture of organic polyether dispersions

Synonym(s):

organic antifoam

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

Recommended Products

biological source

synthetic

Quality Level

form

liquid

technique(s)

microbiological culture: suitable

viscosity

400 cP(lit.)

density

1.01 g/cm3 at 25 °C (lit.)

storage temp.

room temp

Looking for similar products? Visit Product Comparison Guide

General description

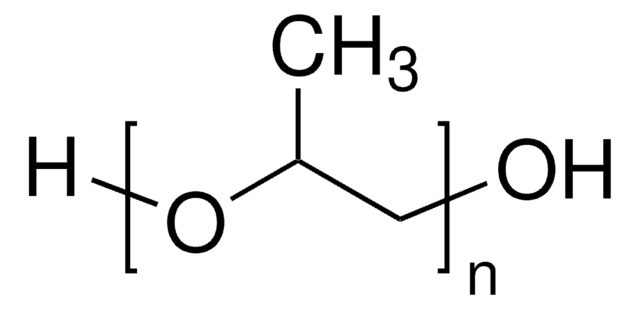

Antifoam function as an effective foam suppressor. Antifoam 204 contains 100% active components and is a mixture of organic non-silicone polypropylene-based polyether dispersions. It does not contain mineral oil. Antifoam 204 can itself be considered a surfactant, but it contains no other surfactants. This product is synthetic and not derived from animal or plant sources. Antifoam 204 can be sterilized repeatedly. The flow properties of Antifoam 204 are such that it can be pumped to a fermenter on an as-needed basis. For use in microbiological media, Sigma recommends a starting concentration of between 0.005% and 0.01%.

Application

Antifoam 204 has been used:

- to suppress bubbling in thylakoid solutions during intramembrane isoprene quantification

- as a component of fed-batch continuous culture fermentation medium

- to suppress severe foaming in fermenter

Features and Benefits

- Highly versatile surfactant for your cell biology and biochemical research

- Suitable for microbiological culture

Other Notes

Contains 100% active components and is a mixture of non-silicone organic defoamers in a polyol dispersion. Can be sterilized repeatedly.

For additional information on our range of Biochemicals, please complete this form.

Storage Class

10 - Combustible liquids

wgk_germany

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Physiology of Aspergillus niger in oxygen-limited continuous cultures: Influence of aeration, carbon source concentration and dilution rate

Diano A, et al.

Biotechnology and Bioengineering, 103(5), 956-965 (2009)

Ultrasound-assisted fermentation enhances bioethanol productivity

Sulaiman AZ, et al.

Biochemical Engineering Journal, 54(3), 141-150 (2011)

A novel noncovalent complex of chorismate mutase and DAHP synthase from Mycobacterium tuberculosis: protein purification, crystallization and X-ray diffraction analysis

M Okvist, et al.

Acta Crystallographica Section F, Structural Biology and Crystallization Communications, 65(10), 1048-1052 (2009)

Concentration of isoprene in artificial and thylakoid membranes

Harvey CM, et al.

Journal of Bioenergetics and Biomembranes, 47(5), 419-429 (2015)

Erin E Johnson et al.

Bioresource technology, 209, 1-7 (2016-03-08)

Waste crude glycerol from biodiesel production can be used to produce biobutanol using Clostridium pasteurianum with the main products being n-butanol, 1,3-propanediol (PDO) and ethanol. There has been much discrepancy and mystery around the cause and effect of process parameters

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service