901769

Flexible conductive silver paste for screen printing

Synonym(s):

Ag ink, C2080415P2, Conductive ink, Silver ink

About This Item

Recommended Products

description

Coverage: 250-270 cm2 per g (using a 230 mesh stainless steel screen)

Flash point: 90°C

Solid content: 44-46% (at 130°C)

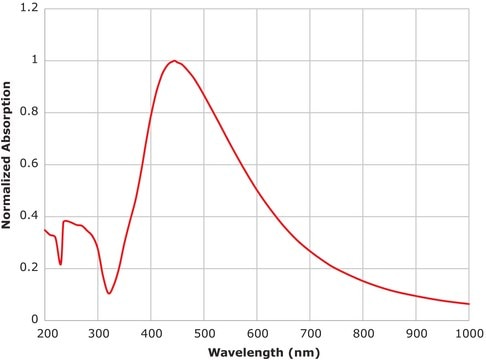

Volume resistivity: 925 ohm cm at 60°C

527 ohm cm at 130°C

form

paste

hardness

5B (pencil hardness)

viscosity

0.72-1.78 Pa.s (Haake RS1 C20/2° TiL at 230 sec-1 at 25°C)

Related Categories

General description

The ink has undergone electrical and mechanical testing which has shown that it is very flexible.

Application

- Screen-printable silver paste material for semitransparent and flexible metal–semiconductor–metal photodetectors with liquid-phase procedure: This study presents a flexible MSM photodetector using conductive Ag paste electrodes made through a screen-printing liquid-phase process, offering insights into the semitransparency of Ag paste solutions (Tsai et al., 2022).

- Effect of polymer binder on the transparent conducting electrodes on stretchable film fabricated by screen printing of silver paste: This research examines the role of polymer binders in silver pastes used on flexible polyurethane and polyester films, focusing on rheological properties (Lim et al., 2017).

- Deposition of high conductivity low silver content materials by screen printing: Investigates novel polymer inks alongside traditional paste materials for their application in both rigid and flexible circuit printing, emphasizing cost-effectiveness and performance (Jewell et al., 2015).

- Printability of the screen-printed strain sensor with carbon black/silver paste for sensitive wearable electronics: Explores the use of carbon black/Ag nanocomposites in pastes for flexible printed electronic products, enhancing the sensitivity and flexibility of these devices (Qi et al., 2020).

- High-concentration copper nanoparticles synthesis process for screen-printing conductive paste on flexible substrate: While focusing on copper, this study provides relevant comparisons to silver pastes, detailing formulations suitable for screen-printing on flexible polyester substrates (Tam and Ng, 2015).

Features and Benefits

Low silver content paste presenting low resistivity, good flexibility and good adhesion on the mentioned substrates

Physical properties

Sheet resistivity: 15-20mΩ/square at 25μm

30-45mΩ/square at 10μm

Bending test: ink survived 3 cycles

(Substrate is creased and bent internally and externally with a 2kg weight.

The test piece has failed when the resistance reaches 10 times the initial value.)

Double curing: aging factor of -0.7%after double curing at 150°C for 15min

How water test: aging factor of -0.2% after boiling for 1hour

Preparation Note

Please mix well the paste without introducing air bubbles prior to screen printing.

Screen Printing Equipment: semi-automatic, manual

Ink Screen Life: >3 hours

Screen Types: suitable for use with polyester or stainless steel meshes in the range of 156 to 325 tpi.

Typical Drying Conditions: Dry at 130°C - 150°C for 10-30 minutes or on a belt dryer with air flow that sees 130°C-170°C for 5-10 minutes.

Clean Up Solvent: ethoxy propanol or sericol

Substrate: polyimide, PET, PEN and can also be printed on more rigid substrates such as alumina

Legal Information

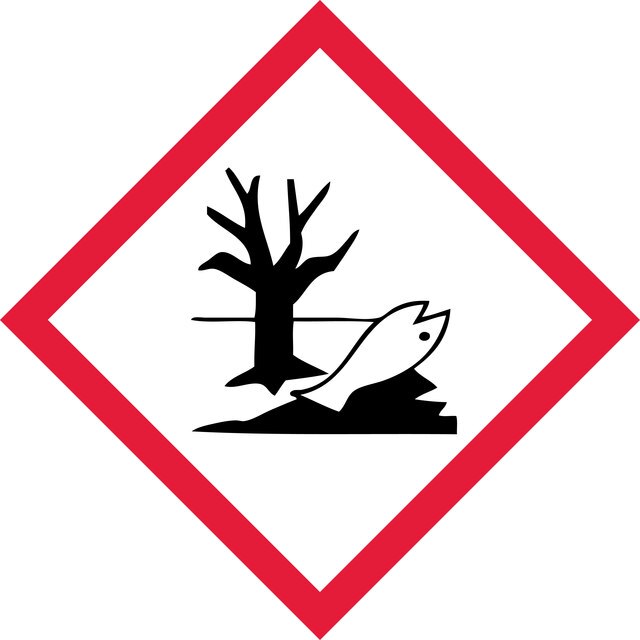

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Aquatic Acute 1 - Aquatic Chronic 1

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Flash Point(F)

194.0 °F

Flash Point(C)

90 °C

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Dr. Chan and researchers highlight flexible transistors are the building blocks of next-generation soft electronics. Among all the reported material systems that can be fabricated by researchers, such as circuits, biosensors, stretchable displays, and others,1–5 small molecular weight organic semiconductors are among the most promising candidates for flexible transistor applications. For these small molecular weight organic semiconductors, the semiconductor forming the conductive channel dominates the device performance.

Professor Tokito and Professor Takeda share their new materials, device architecture design principles, and performance optimization protocols for printed and solution-processed, low-cost, highly flexible, organic electronic devices.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service