ERMEC591

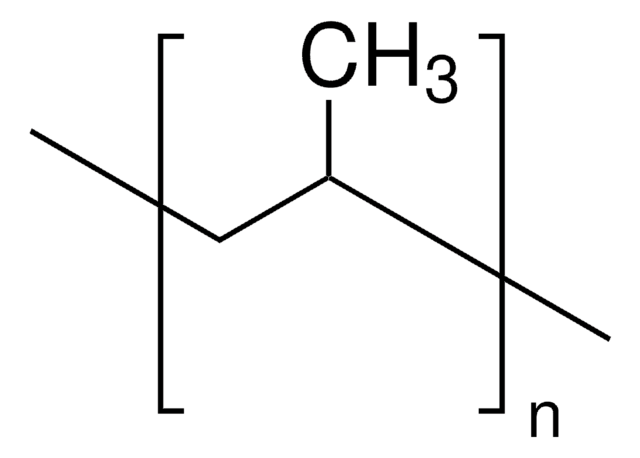

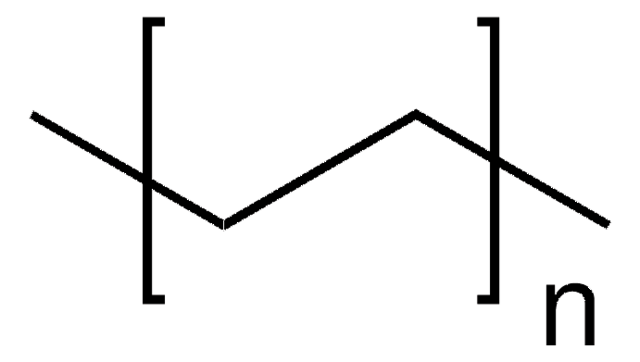

Polypropylen (PP)

ERM®, certified reference material

Synonym(e):

Polypropylen

About This Item

Empfohlene Produkte

Qualität

certified reference material

Agentur

ERM®

Hersteller/Markenname

JRC

Dichte

0.9 g/mL at 25 °C (lit.)

Anwendung(en)

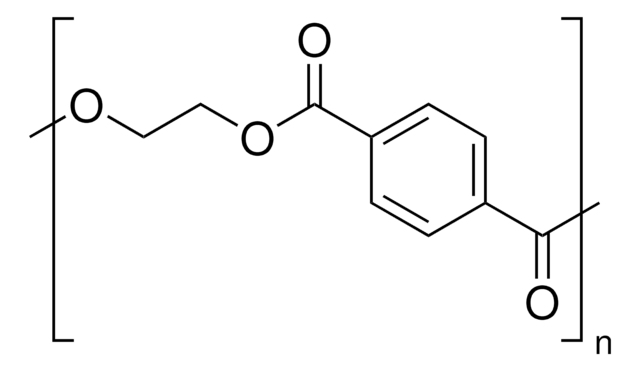

chemicals and industrial polymers

Format

neat

Lagertemp.

−20°C

SMILES String

CC=C

InChI

1S/C22H42O3/c1-2-3-4-5-11-14-17-20-21(25-20)18-15-12-9-7-6-8-10-13-16-19-22(23)24/h20-21H,2-19H2,1H3,(H,23,24)/t20-,21+/m1/s1

InChIKey

NSYDMBURIUSUDH-RTWAWAEBSA-N

Suchen Sie nach ähnlichen Produkten? Aufrufen Leitfaden zum Produktvergleich

Hinweis zur Analyse

ERMEC591

Rechtliche Hinweise

Lagerklassenschlüssel

11 - Combustible Solids

WGK

WGK 3

Flammpunkt (°F)

Not applicable

Flammpunkt (°C)

Not applicable

Choose from one of the most recent versions:

Analysenzertifikate (COA)

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Kundensupport

Besitzen Sie dieses Produkt bereits?

In der Dokumentenbibliothek finden Sie die Dokumentation zu den Produkten, die Sie kürzlich erworben haben.

Kunden haben sich ebenfalls angesehen

Unser Team von Wissenschaftlern verfügt über Erfahrung in allen Forschungsbereichen einschließlich Life Science, Materialwissenschaften, chemischer Synthese, Chromatographie, Analytik und vielen mehr..

Setzen Sie sich mit dem technischen Dienst in Verbindung.