Z683485

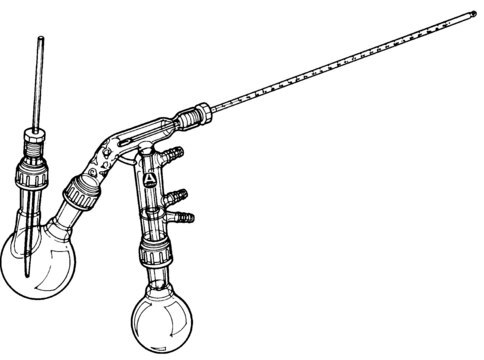

Aldrich® Kugelrohr™ short-path distillation apparatus

AC/DC input 230 V AC, European 2-pin plug

Synonym(e):

apparatus for distillation, ball tube distillation, distillation apparatus, distilling apparatus, fractional distillation apparatus, glass distillation apparatus, kugelrohr apparatus, kugelrohr distillation, short path distillation apparatus, vacuum distillation apparatus

About This Item

Empfohlene Produkte

Parameter

220 °C temp. limit

B × H × T

25 in. × 18 in. × 11 in.

Suchen Sie nach ähnlichen Produkten? Aufrufen Leitfaden zum Produktvergleich

Verwandte Kategorien

Allgemeine Beschreibung

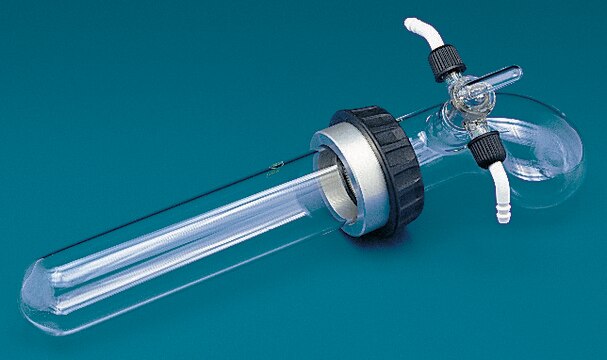

High Vacuum Capability and Safe Front Loading Design

Distillation Applications:

- Heat-sensitive compounds

- Liquids and low-melting solids from polymers and tars

- Removes color and particulates

- Suitable for sublimation and solvent evaporation

Features:

- Air bath oven distills up to 230°C

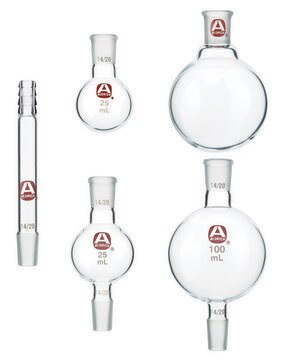

- 25 mL to 2 L flask capacity

- Front Loading oven door with safety glass viewing window

- Interchangeable PTFE support bearings for flask joint 14/20

- Digital, thermocouple temperature control

- Front panel with controls for temperature, vacuum and motor drive

- Adjustable receiving flask cooling bath

- Oscillating drive motor

Specifications:

- Oven flask size range: 25 mL to 2 L

- Heating range: ambient to 230°C, +/- 3°C across span after stabilization

- Power: 120/240 VAC +/- 10%, 50/60 Hz +/- 3%, detachable power cord

- Fuses: Heater 7.5 A, Vac 2.5 A, Power input 10 A

- Heater: 900 W

- Size: 25 in. W x 11 in. D x 18 in. H, (30 in. clearance required with door open)

- Rotation: 270 deg each direction

- Operating environment: 32 to 40°C, 0 to 90% RH, noncondensing

- CE, WEEE and RoHS complilant

Ordering Note: Purchase Kugelrohr glassware separately.

Note: A trap between the receiving flask/s and vacuum pump is recommended.

Applications related to marijuana extraction/production are not supported.

Typical operation:

Step 1. Fill the load (oven) flask (25 mL to 2 L) one-third full with distillable material. Connect the load flask to the motor drive coupling inside the oven. Connect the load flask to a horizontal receiving flask outside the oven. Connect a straight tube to the receiving flask and to a vacuum source with rubber tubing.

Step 2. A vacuum pump may be plugged into the receptacle on the rear of the oven and switched on and off from the Kugelrohr front control panel.

Step 3. Fill cooling tray with ice.

Step 4. Turn on the Kugelrohr main power switch. Set the distillation temperature on the front control panel, turn on the motor drive and vacuum pump.

Step 5. Collect distillate in the horizontal receiving flask outside the oven.

Rechtliche Hinweise

Ersatzteil

Zubehör

Ähnliches Produkt

Analysenzertifikate (COA)

Suchen Sie nach Analysenzertifikate (COA), indem Sie die Lot-/Chargennummer des Produkts eingeben. Lot- und Chargennummern sind auf dem Produktetikett hinter den Wörtern ‘Lot’ oder ‘Batch’ (Lot oder Charge) zu finden.

Besitzen Sie dieses Produkt bereits?

In der Dokumentenbibliothek finden Sie die Dokumentation zu den Produkten, die Sie kürzlich erworben haben.

Kunden haben sich ebenfalls angesehen

Unser Team von Wissenschaftlern verfügt über Erfahrung in allen Forschungsbereichen einschließlich Life Science, Materialwissenschaften, chemischer Synthese, Chromatographie, Analytik und vielen mehr..

Setzen Sie sich mit dem technischen Dienst in Verbindung.